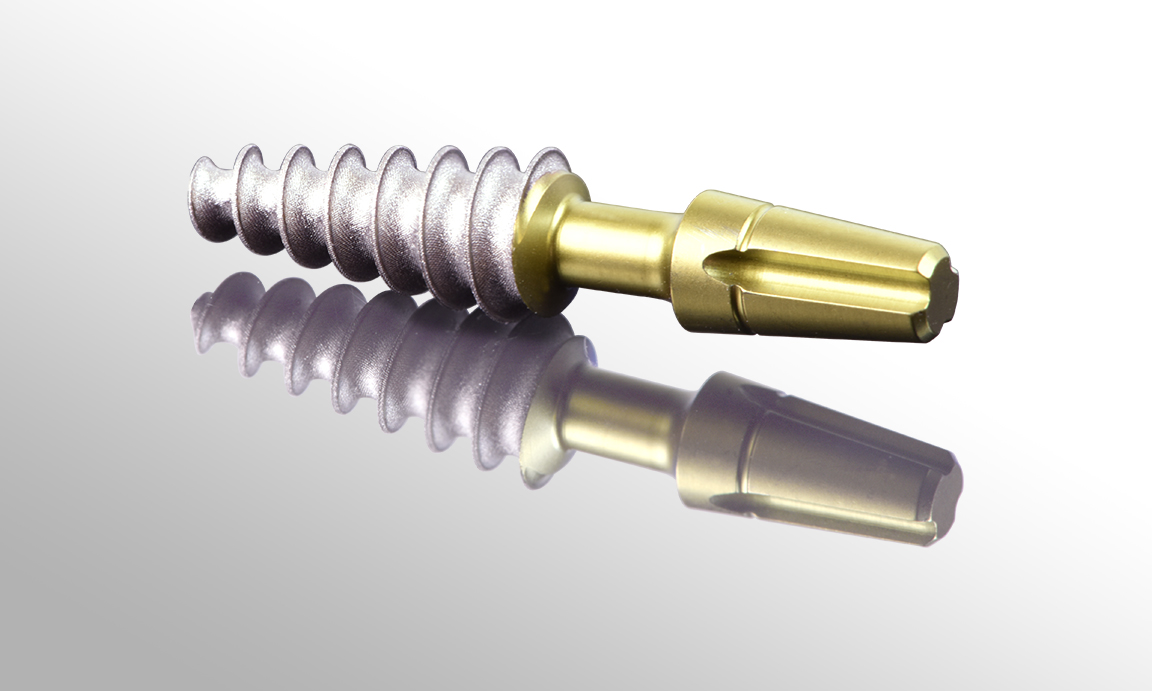

GCS®

GCS® implants are suitable for crowns, bridges and bars. With the correct surgical procedure and good bone quality, the compression screws design permits to incorporate the restoration in an immediate loading protocol (incorporation of the prosthesis within a maximum of three days). Today, GCS® implants are routinely used for immediately loaded bridge constructions. The single-piece design saves costs, effort and prevents the problem of screw loosening. In extraction cases, GCS® and GBC® are combined.

No-Itis® Laser

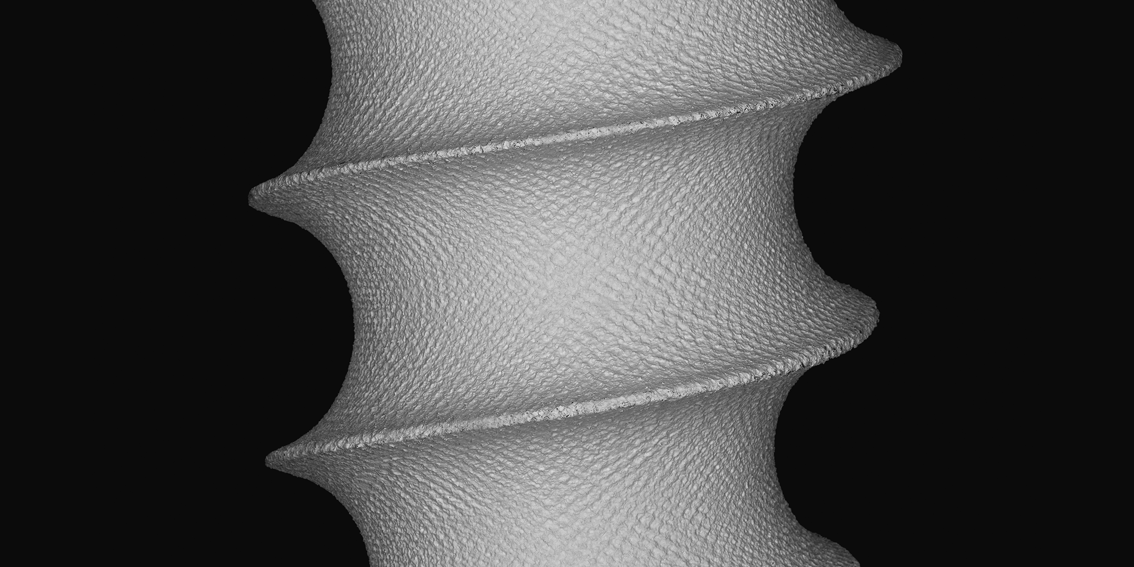

The surface treatment for onewaybiomed® implants is created with the latest generation of robotic tools for laser ablation. This technology of high precision creates roughness in the implant through a mesh of hemispherical micrometric pores, with a defined, always identical size and shape and with a symmetrical distribution.

The result is a more adequate topography, which provides the most suitable conditions for the osseointegration of the implant, but at the same time it is, and behaves like, a smooth surface at a micrometric (cellular) level. This means that while bone grows well on this surface, the adhesion of bacteria to the same surface is significantly reduced.

No-Itis® laser surfaceProsthetics

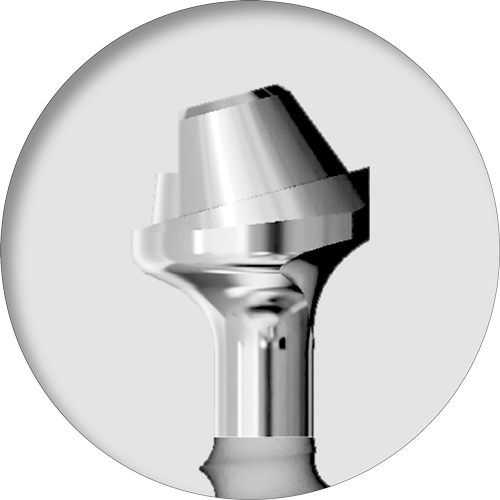

Large head

Cementable

Small head

Cementable

Multi-Unit

Screwable

Ball head

Removable

Matching Instruments

onewaybiomed® offers high quality drills with depth markings to match the endosseous implant shape. Due to the extremely high cutting performance, it is possible to work without pressure. Compared to other drills, these develop 55% less drilling temperature. Thanks to the color coding, the drills can be quickly identified during and before the procedure.

Variants

GCS ROOT®

GCS ROOT®

GCS ROOT® implants are used for crowns, bridges and bars. The compression screw design permits to incorporate the restoration in an immediate loading protocol (incorporation of the prosthesis within max. three days). The single-piece design reduces costs, the danger of periimplantitis and it eliminates the hazzles of screw loosening. GCS ROOT® implants are straight with prosthetic head for cementation.

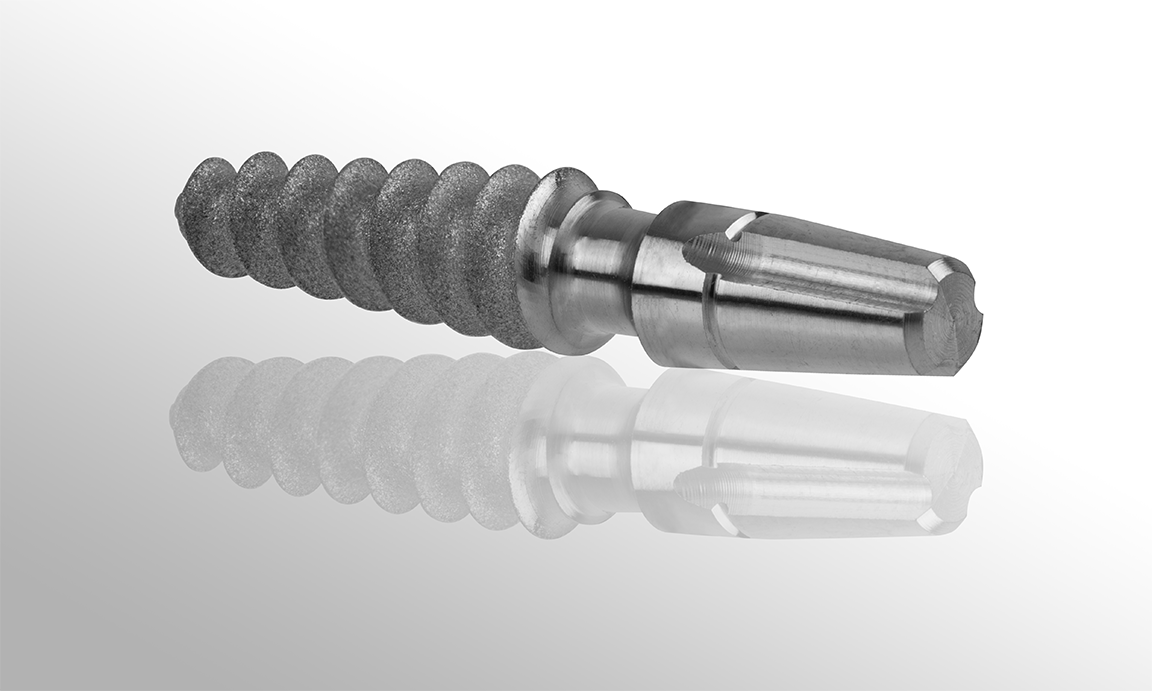

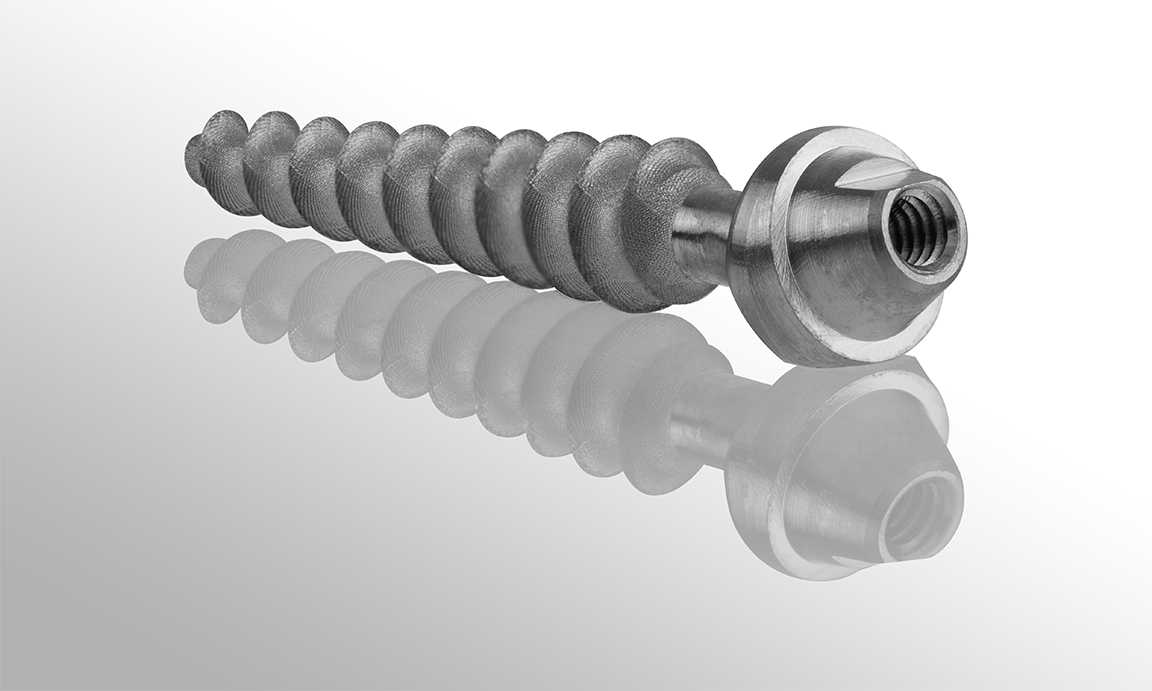

GCS® Classic

GCS® Classic

GCS® Classic implants have a compression thread and can be supplied in the immediate loading protocol, for which only very few working steps are required. The implant design has no micro gap. The implants are made of highly resistant titanium alloy.

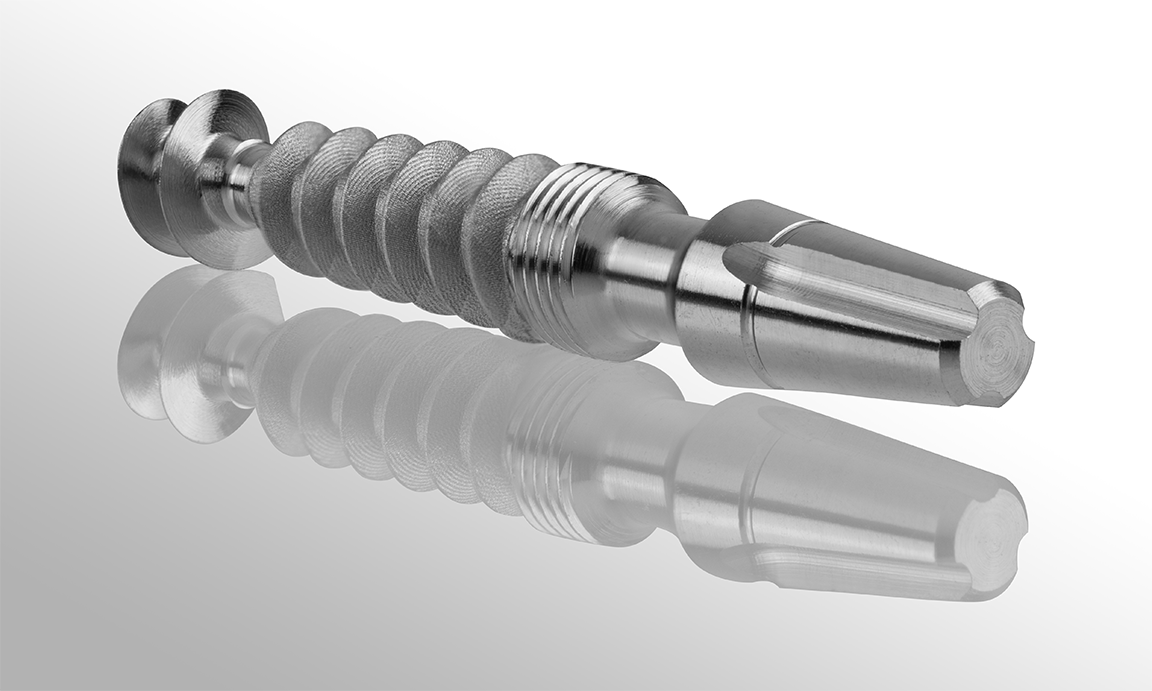

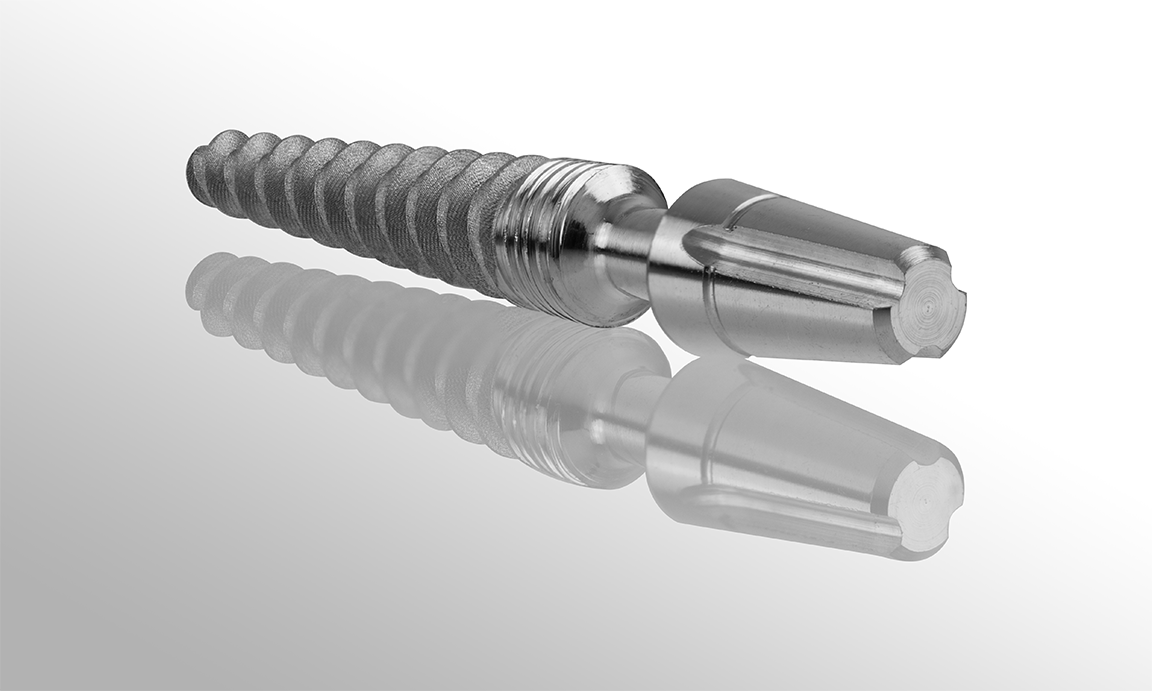

GCS® Classic X

GCS® Classic X

GCS® Classic X implants have a compression thread and can be supplied in the immediate loading protocol, for which only very few working steps are required. The implant design has no micro gap. The implants are made of highly resistant titanium alloy.

GCS® B

GCS® B

GCS® B implants are suitable for bridges in the reduced-load range. The bendable implant now offers double safety:

- 1. Torque reduction by pre-compression with the congruent bone-expanding screw

- 2. Safety head with predetermined breaking point and dual square

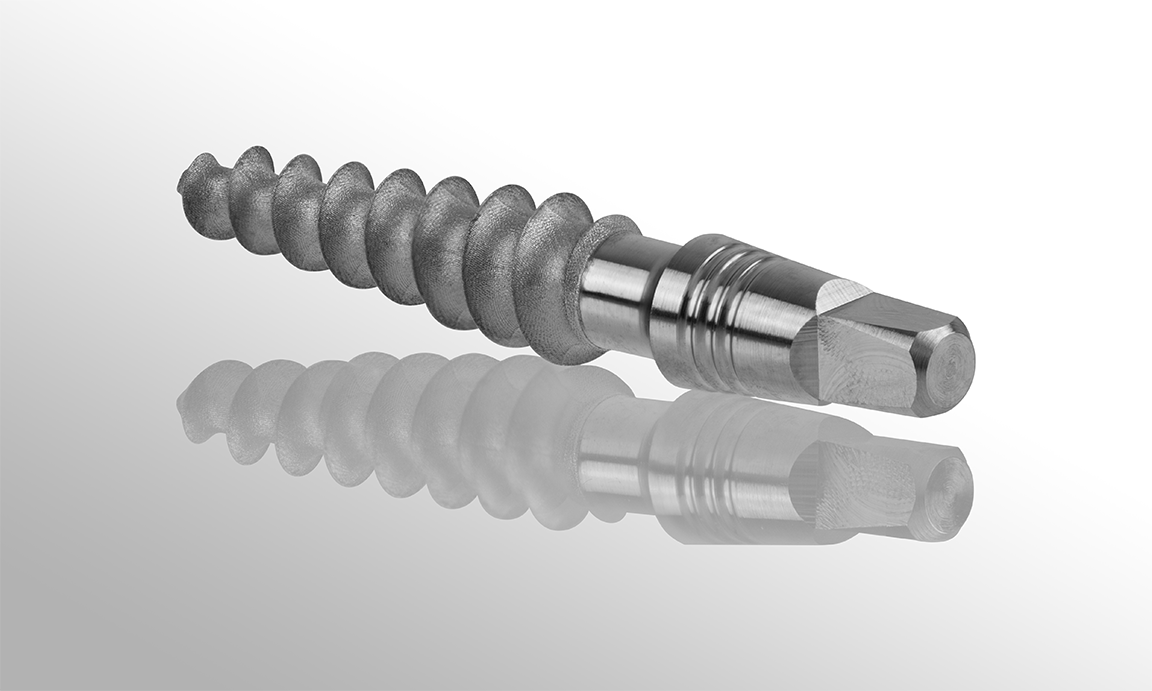

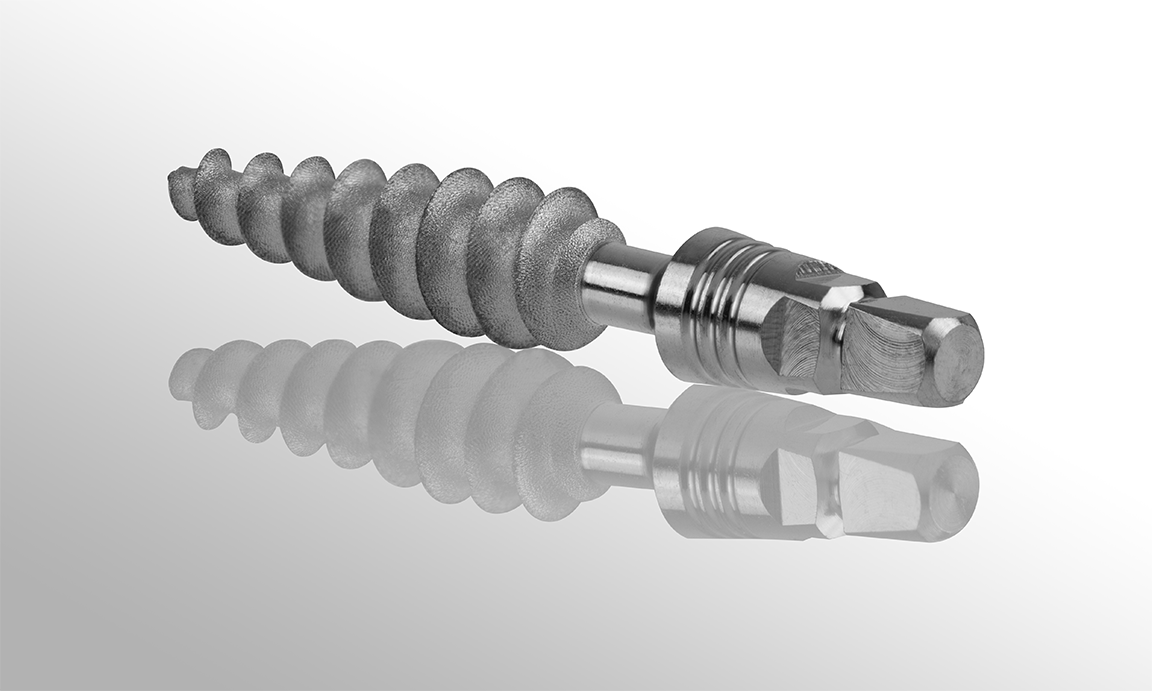

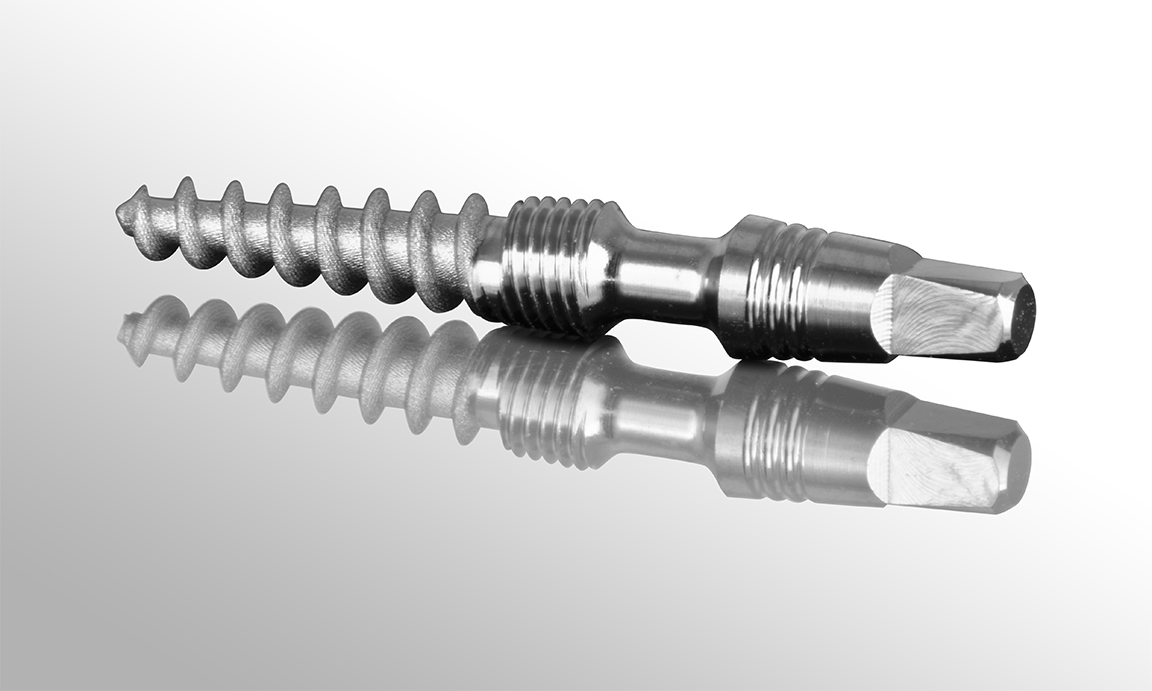

GCS® Plus

GCS® Plus

GCS® Plus implants have vertical grooves for anti-rotation protection and have no micro gap. The polished apical cutting thread is used for anchorage in the opposite cortical. The implant design combines the advantages of the compression screw with the advantages of the bicortical screw. Thus, in addition to the bone compression, the anchorage is in the 2nd cortical bone (opposite cortical bone). The endosseous part is provided with the special No-Itis® laser surface. Optimum primary stability thanks to micro thread and aggressive apical thread. GCS® Plus implants can be used in the maxilla and mandible and are made of highly resistant titanium alloy.

GCS® TX

GCS® TX

GCS® TX implants are compression screw implants with an extended polished and bendable neck. The implants are suitable for anchorages in the tuberosity and in regions with large mucosal thickness and are preferably used without flap formation. The nominal diameter is reached at the widest part of the compression thread.

GCS® MU

GCS® MU

GCS® MU implants feature a pre-angulation of 15 degrees and can also be bent additionally, using the insertion tool. In conjunction with the clinically possible rotational positions of the head, virtually all angulations can be realised. The implants are made of highly resistant titanium alloy.

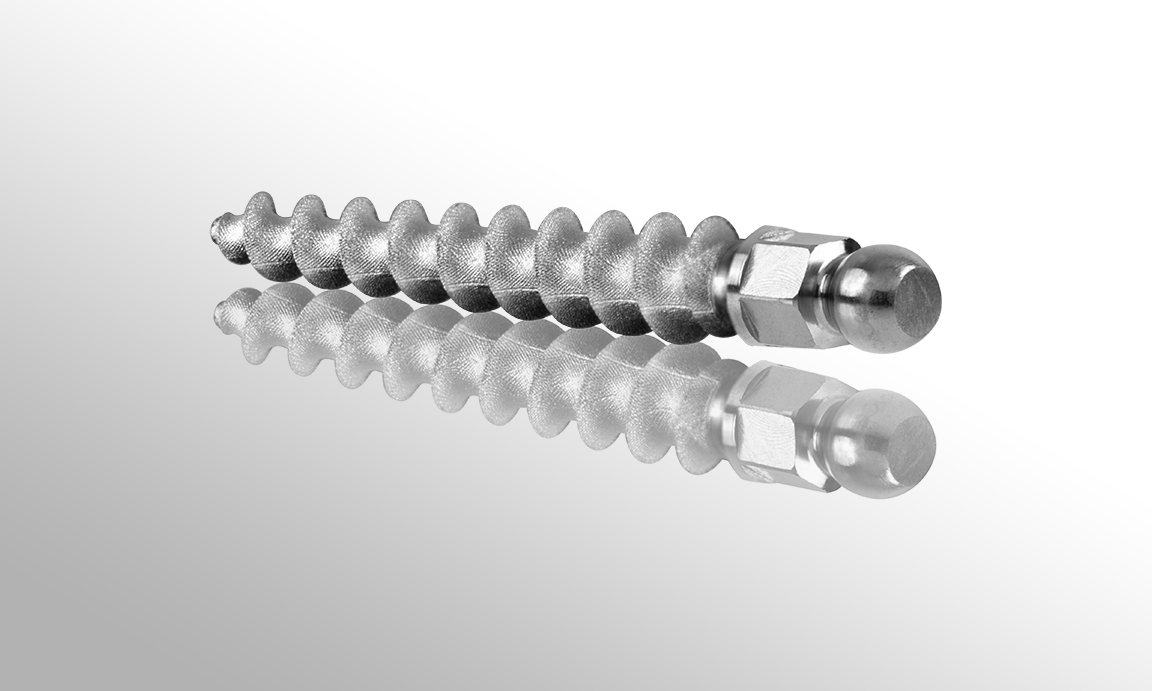

GCS® K

GCS® K

GCS® K implants are perfectly manufactured precision implants with a ball head. They are used for fixation of prostheses with nylon caps and are made of titanium alloy.

GCS® M

GCS® M

GCS® M implants are suitable for the anterior region and tight gaps and are preferably used in an immediate loading protocol. Unlike other compression screws, the polished neck has a cylindrical shape. The cortical is sealed, good retention is achieved and the bone is protected against infections. The endosseous implant part compresses the cancellous bone areas.

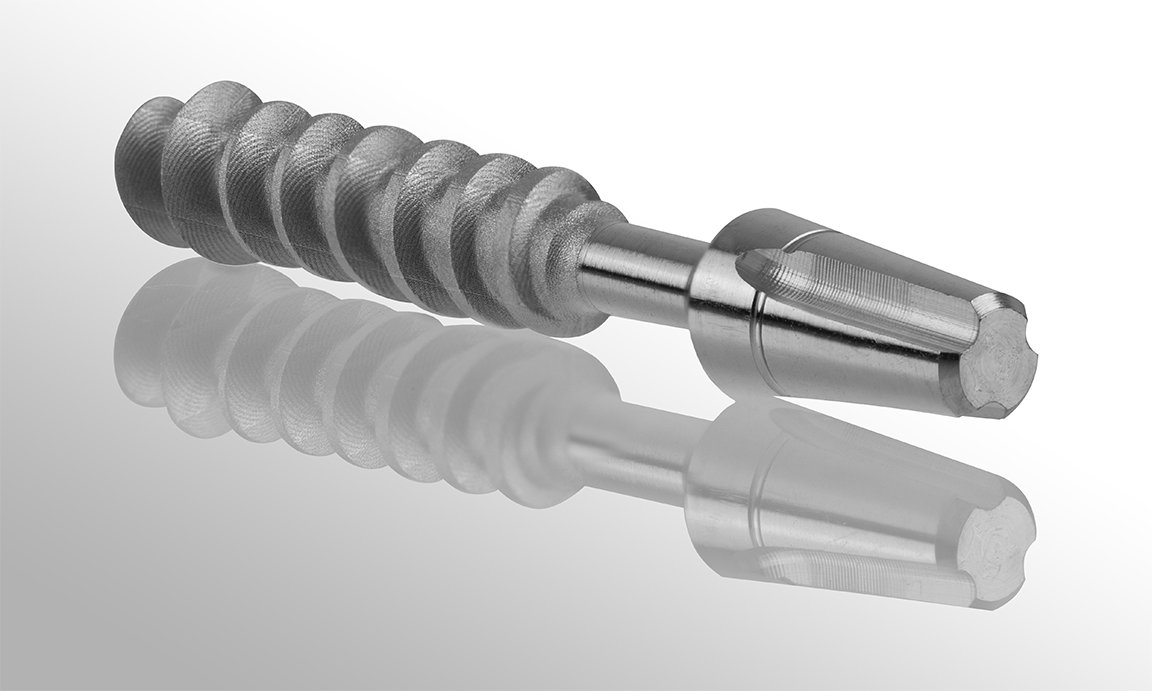

GCS® Micro

GCS® Micro

GCS® Micro implants have vertical grooves for anti-rotation protection. The single-piece design reduces costs, avoids the danger of periimplantitis and prevents the problem of screw loosening. Suitable for all applications, crowns, bridges and bars. The implant design has an optimal primary stability thanks to the micro thread and the compression screw design. The enossal part is provided with the special No-Itis® laser surface.